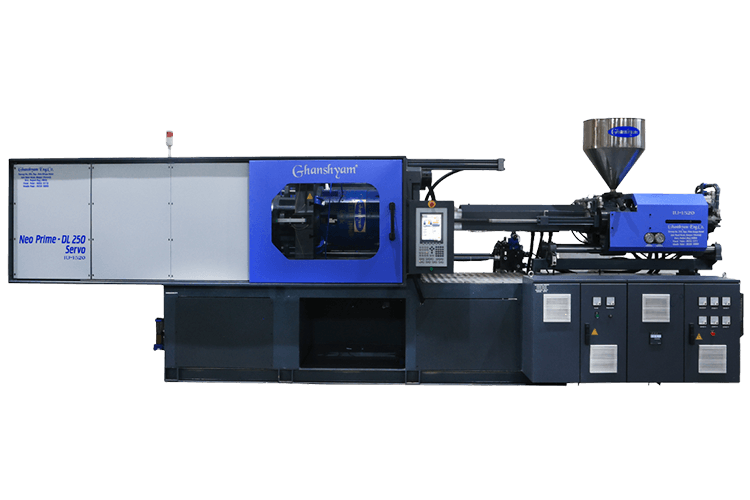

NEO Prime DL Series

Technical Specification

| Model | 250 Ton | |||||||||||||||

| International Size | 2500-905 | 2500-905 | 2500-1520 | 2500-1520 | 2500-2350 | |||||||||||

| Clamping Unit | Unit | |||||||||||||||

| Clamp Forge | Ton | 250 | 250 | 250 | 250 | 250 | ||||||||||

| Clamp Stroke | MM | 850 | 850 | 850 | 850 | |||||||||||

| Min. Mould Height | MM | 250/400 | 250/400 | 250/400 | 250/400 | 250/400 | ||||||||||

| Max. Daylight | MM | 1100/1250 | 1100/1250 | 1100/1250 | 1100/1250 | 1100/1250 | ||||||||||

| Dist.Bet.TieBar | MM | 630×630 | 630×630 | 630×630 | 630×630 | 630×630 | ||||||||||

| Platen Size | MM | 880×880 | 880×880 | 880×880 | 880×880 | 880×880 | ||||||||||

| Ejector Stroke | MM | 170 | 170 | 170 | 170 | 170 | ||||||||||

| Ejector Forge | Ton | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | ||||||||||

| Injection Unit | ||||||||||||||||

| Screw Size | MM | 45 | 50 | 60 | 45 | 50 | 60 | 50 | 60 | 70 | 50 | 60 | 70 | 60 | 70 | 80 |

| L/D Ratio | 26.7 | 24 | 20 | 26.7 | 24 | 20 | 28 | 23.3 | 20 | 28 | 23.3 | 20 | 26.6 | 22.8 | 20 | |

| Screw Stroke | MM | 245 | 245 | 245 | 245 | 245 | 245 | 280 | 280 | 280 | 280 | 280 | 280 | 315 | 315 | 315 |

| Inj. Capacity (GPPS) | GMS | 370 | 457 | 658 | 370 | 457 | 658 | 522 | 752 | 1023 | 522 | 752 | 1023 | 846 | 1151 | 1503 |

| Inj. Pressure Max. | BAR | 2323 | 1882 | 1316 | 2323 | 1882 | 1316 | 2813 | 1953 | 1435 | 2813 | 1953 | 1435 | 2640 | 1940 | 1485 |

| Theoretical Displacement | CC | 389 | 480 | 692 | 389 | 480 | 692 | 549 | 791 | 1077 | 549 | 791 | 1077 | 890 | 1211 | 1582 |

| Inj. Rate | CC/Sec | 114 | 140 | 202 | 159 | 197 | 284 | 132 | 191 | 260 | 170 | 245 | 334 | 181 | 247 | 323 |

| Heating Capacity | KW | 13.5 | 13.5 | 13.5 | 13.5 | 13.5 | 13.5 | 21 | 21 | 21 | 21 | 21 | 21 | 24 | 24 | 24 |

| No. of Heating Zone (Barrel + Nozzle) | 4+1 | 4+1 | 4+1 | 4+1 | 4+1 | 4+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | |

| Nozzle Contact Force | Ton | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| General Data | ||||||||||||||||

| Motor Power/Servo Motor | KW | 14.9/20.4 | 22.3/28.7 | 22.3/28.7 | 29.8/36.7 | 29.8/36.7 | ||||||||||

| Total Connected Load | KW | 28.4 | 35.8 | 43.3 | 50.8 | 53.8 | ||||||||||

| Model | 350 Ton | |||||||||||||||

| International Size | 3500-1520 | 3500-1520 | 3500-2350 | 3500-2350 | ||||||||||||

| Clamping Unit | Unit | |||||||||||||||

| Clamp Forge | Ton | 350 | 350 | 350 | 350 | |||||||||||

| Clamp Stroke | MM | 1100 | 1100 | 1100 | 1100 | |||||||||||

| Min. Mould Height | MM | 300/600 | 300/600 | 300/600 | 300/600 | |||||||||||

| Max. Daylight | MM | 1400/1700 | 1400/1700 | 1400/1700 | 1400/1700 | |||||||||||

| Dist.Bet.TieBar | MM | 720×720 | 720×720 | 720×720 | 720×720 | |||||||||||

| Platen Size | MM | 1020×1020 | 1020×1020 | 1020×1020 | 1020×1020 | |||||||||||

| Ejector Stroke | MM | 210 | 210 | 210 | 210 | |||||||||||

| Ejector Forge | Ton | 7.5 | 7.5 | 7.5 | 7.5 | |||||||||||

| Injection Unit | ||||||||||||||||

| Screw Size | MM | 50 | 60 | 70 | 50 | 60 | 70 | 60 | 70 | 80 | 60 | 70 | 80 | |||

| L/D Ratio | 28 | 23.3 | 20 | 28 | 23.3 | 20 | 26.6 | 22.8 | 20 | 26.6 | 22.8 | 20 | ||||

| Screw Stroke | MM | 280 | 280 | 280 | 280 | 280 | 280 | 315 | 315 | 315 | 315 | 315 | 315 | |||

| Inj. Capacity (GPPS) | GMS | 522 | 752 | 1023 | 522 | 752 | 1023 | 846 | 1151 | 1503 | 846 | 1151 | 1503 | |||

| Inj. Pressure Max. | BAR | 2813 | 1953 | 1435 | 2813 | 1953 | 1435 | 2640 | 1940 | 1485 | 2640 | 1940 | 1485 | |||

| Theoretical Displacement | CC | 549 | 791 | 1077 | 549 | 791 | 1077 | 890 | 1211 | 1582 | 890 | 1211 | 1582 | |||

| Inj. Rate | CC/Sec | 132 | 191 | 260 | 170 | 245 | 334 | 200 | 272 | 356 | 242 | 330 | 431 | |||

| Heating Capacity | KW | 21 | 21 | 21 | 21 | 21 | 21 | 24 | 24 | 24 | 24 | 24 | 24 | |||

| No. of Heating Zone (Barrel + Nozzle) | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | ||||

| Nozzle Contact Force | Ton | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |||

| General Data | ||||||||||||||||

| Motor Power/Servo Motor | KW | 22.3/28.7 | 29.8/36.7 | 37.25/48/td> | 44.7/60 | |||||||||||

| Total Connected Load | KW | 43.3 | 50.8 | 61.25 | 68.7 | |||||||||||

| Total Oil Capacity (Main Tank) | Liter | 720 | 720 | 720 | 720 | |||||||||||

| Oil Tank Capacity (Prefill Tank) | Liter | 700 | 700 | 700 | 700 | |||||||||||

| Machine Dimension (L – W – H) | MM | 8300 x 1950 x 2700 | 8300 x 1950 x 2700 | 8500 x 1950 x 2700 | 8500 x 1950 x 2700 | |||||||||||

| Machine Weight | KGS | 17500 | 17500 | 18000 | 18000 | |||||||||||

Technical Specification

250 Ton

| Model | 250 Ton | |||||||||||||||

| International Size | 2500-905 | 2500-905 | 2500-1520 | 2500-1520 | 2500-2350 | |||||||||||

| Clamping Unit | Unit | |||||||||||||||

| Clamp Forge | Ton | 250 | 250 | 250 | 250 | 250 | ||||||||||

| Clamp Stroke | MM | 850 | 850 | 850 | 850 | |||||||||||

| Min. Mould Height | MM | 250/400 | 250/400 | 250/400 | 250/400 | 250/400 | ||||||||||

| Max. Daylight | MM | 1100/1250 | 1100/1250 | 1100/1250 | 1100/1250 | 1100/1250 | ||||||||||

| Dist.Bet.TieBar | MM | 630×630 | 630×630 | 630×630 | 630×630 | 630×630 | ||||||||||

| Platen Size | MM | 880×880 | 880×880 | 880×880 | 880×880 | 880×880 | ||||||||||

| Ejector Stroke | MM | 170 | 170 | 170 | 170 | 170 | ||||||||||

| Ejector Forge | Ton | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | ||||||||||

| Injection Unit | ||||||||||||||||

| Screw Size | MM | 45 | 50 | 60 | 45 | 50 | 60 | 50 | 60 | 70 | 50 | 60 | 70 | 60 | 70 | 80 |

| L/D Ratio | 26.7 | 24 | 20 | 26.7 | 24 | 20 | 28 | 23.3 | 20 | 28 | 23.3 | 20 | 26.6 | 22.8 | 20 | |

| Screw Stroke | MM | 245 | 245 | 245 | 245 | 245 | 245 | 280 | 280 | 280 | 280 | 280 | 280 | 315 | 315 | 315 |

| Inj. Capacity (GPPS) | GMS | 370 | 457 | 658 | 370 | 457 | 658 | 522 | 752 | 1023 | 522 | 752 | 1023 | 846 | 1151 | 1503 |

| Inj. Pressure Max. | BAR | 2323 | 1882 | 1316 | 2323 | 1882 | 1316 | 2813 | 1953 | 1435 | 2813 | 1953 | 1435 | 2640 | 1940 | 1485 |

| Theoretical Displacement | CC | 389 | 480 | 692 | 389 | 480 | 692 | 549 | 791 | 1077 | 549 | 791 | 1077 | 890 | 1211 | 1582 |

| Inj. Rate | CC/Sec | 114 | 140 | 202 | 159 | 197 | 284 | 132 | 191 | 260 | 170 | 245 | 334 | 181 | 247 | 323 |

| Heating Capacity | KW | 13.5 | 13.5 | 13.5 | 13.5 | 13.5 | 13.5 | 21 | 21 | 21 | 21 | 21 | 21 | 24 | 24 | 24 |

| No. of Heating Zone (Barrel + Nozzle) | 4+1 | 4+1 | 4+1 | 4+1 | 4+1 | 4+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | |

| Nozzle Contact Force | Ton | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| General Data | ||||||||||||||||

| Motor Power/Servo Motor | KW | 14.9/20.4 | 22.3/28.7 | 22.3/28.7 | 29.8/36.7 | 29.8/36.7 | ||||||||||

| Total Connected Load | KW | 28.4 | 35.8 | 43.3 | 50.8 | 53.8 | ||||||||||

350 Ton

| Model | 350 Ton | |||||||||||||||

| International Size | 3500-1520 | 3500-1520 | 3500-2350 | 3500-2350 | ||||||||||||

| Clamping Unit | Unit | |||||||||||||||

| Clamp Forge | Ton | 350 | 350 | 350 | 350 | |||||||||||

| Clamp Stroke | MM | 1100 | 1100 | 1100 | 1100 | |||||||||||

| Min. Mould Height | MM | 300/600 | 300/600 | 300/600 | 300/600 | |||||||||||

| Max. Daylight | MM | 1400/1700 | 1400/1700 | 1400/1700 | 1400/1700 | |||||||||||

| Dist.Bet.TieBar | MM | 720×720 | 720×720 | 720×720 | 720×720 | |||||||||||

| Platen Size | MM | 1020×1020 | 1020×1020 | 1020×1020 | 1020×1020 | |||||||||||

| Ejector Stroke | MM | 210 | 210 | 210 | 210 | |||||||||||

| Ejector Forge | Ton | 7.5 | 7.5 | 7.5 | 7.5 | |||||||||||

| Injection Unit | ||||||||||||||||

| Screw Size | MM | 50 | 60 | 70 | 50 | 60 | 70 | 60 | 70 | 80 | 60 | 70 | 80 | |||

| L/D Ratio | 28 | 23.3 | 20 | 28 | 23.3 | 20 | 26.6 | 22.8 | 20 | 26.6 | 22.8 | 20 | ||||

| Screw Stroke | MM | 280 | 280 | 280 | 280 | 280 | 280 | 315 | 315 | 315 | 315 | 315 | 315 | |||

| Inj. Capacity (GPPS) | GMS | 522 | 752 | 1023 | 522 | 752 | 1023 | 846 | 1151 | 1503 | 846 | 1151 | 1503 | |||

| Inj. Pressure Max. | BAR | 2813 | 1953 | 1435 | 2813 | 1953 | 1435 | 2640 | 1940 | 1485 | 2640 | 1940 | 1485 | |||

| Theoretical Displacement | CC | 549 | 791 | 1077 | 549 | 791 | 1077 | 890 | 1211 | 1582 | 890 | 1211 | 1582 | |||

| Inj. Rate | CC/Sec | 132 | 191 | 260 | 170 | 245 | 334 | 200 | 272 | 356 | 242 | 330 | 431 | |||

| Heating Capacity | KW | 21 | 21 | 21 | 21 | 21 | 21 | 24 | 24 | 24 | 24 | 24 | 24 | |||

| No. of Heating Zone (Barrel + Nozzle) | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 | ||||

| Nozzle Contact Force | Ton | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |||

| General Data | ||||||||||||||||

| Motor Power/Servo Motor | KW | 22.3/28.7 | 29.8/36.7 | 37.25/48/td> | 44.7/60 | |||||||||||

| Total Connected Load | KW | 43.3 | 50.8 | 61.25 | 68.7 | |||||||||||

| Total Oil Capacity (Main Tank) | Liter | 720 | 720 | 720 | 720 | |||||||||||

| Oil Tank Capacity (Prefill Tank) | Liter | 700 | 700 | 700 | 700 | |||||||||||

| Machine Dimension (L – W – H) | MM | 8300 x 1950 x 2700 | 8300 x 1950 x 2700 | 8500 x 1950 x 2700 | 8500 x 1950 x 2700 | |||||||||||

| Machine Weight | KGS | 17500 | 17500 | 18000 | 18000 | |||||||||||

Design Advantages & Features

Features

- Air Ejection.

- Double hydrollic core pull.

- Part drop detect for single cavity.

- Water manifolds.

- Robot interface.

- T – slot platens(90/110 ton).

- Interface for Gas Assisted Injection.

- System Pressure Display on Screen.

- Nozzle contact force by pressure switch.

- Infrared Heaters.

- Mould clamps and fasteners.

- Extended Nozzle with heater.

- Injection Unit with LM guide ways.

Clamping Unit

- Heavy duty 5-point double toggle mechanism.

- High wear resistance & strength gear nut (tie bar nut) gives rigid & positive clamping force.

- Self lubricating toggle bush.

- Wiper seal on both sides of the moving plate on the tie-bar.

- High stiffness platen design with large mould mounting area.

- Five stages mould close-open speed & pressure.

- Multi stage digital speed and pressure setting to operate the mould.

- Linear transducer for accurate clamp position.

- Hard chrome planted high-tensile steel tie – bars with stress relieve design.

- Auto mould height adjustment with hydraulic motor.

- Hydraulic ejector with multiple selections.

- Auto — lubrication based on shot adjustment.

- Linear transducer on ejector cylinder.

- Platen casting design with finite element analysis for maximum rigidity.

- Mould platen with t – slots (140 tons & above).

- All casting passed through a strict ultrasonic test and tensile testing process.

- Separate pressure & speed setting for mould set-up.

- Core pulling system.

- Stage wise actual time display.

- Insert molding program.

- Automatic grease lubrication.

- Anti vibration pad.

- Locating ring on stationary platen.

- Frame with catch tray and guide channels for lubrication oil collection.

- Tapped holes for take — out robot.

- Multi – point ejector system.

Hydraulic System

- Energy efficient variable displacement pump and servo control system.

- Direct reading hydraulic pressure.

- Compact, easily accessible injection and clamping valves to minimize the heat generation.

- Contamination free oil tank with feeler cum – breather.

- Provides high safety main motor shuts down on opening the rear gate.

- Hydraulic directional valve on/off indicator connector.

- Oil temperature limits alarm.

- Audible alarm for filter Clogging.

- ED seal fitting.

Safety Features

- Electrical safety on both front & rear door.

- Magnetic grills in a hopper.

- Provision for M.C.C.B.

- Overload circuit breaker.

- Under voltage – over voltage protection.

- Reverse phase,single phase protection.

- Min.- max. mould height safety.

- Lubrication point blockage alarm.

- Nozzle contact safety.

Injection Unit

- Bimetallic/screw for wear resistance and long life.

- Screw for homogenous elasticizing with modern design.

- Screw back pressure with pressure gauge provision.

- High torque hydraulic motor for better plastification.

- 5-stage injection speed pressure & position control.

- 3-stage injection holding speed pressure & position control.

- Hopper sliding arrangement for material removal.

- Intrusion moulding program.

- Selection of injection time & position both.

- Pre – suck back function and after plasticizing suck back.

- High/low temperature alarm. (Suitable low – high limit).

- Linear potentiometer for injection / plasticizing.

- Auto purging facility.

- Ceramic band heaters for instant heating.

- Barrel heater safety cover.

- Twin cylinder balanced injection system.

- Twin cylinder injection twin unit control. Keep nozzle centering precise thus contributing to the longer life of mould.

- High torque hydro motor for better plastification.

- Screw speed indication on MMI.

- Short circuit proof SSR control circuit for heater bands.

Control System

- Energy meter.

- Multi password facility for operators.

- M.C.C.B. operating mechanism.

- SMPS – switched mode power supply gives linear power supply.

- Star delta motor starter.

- M.C.B. for each heating zone.

- PID temprature controller for accurate control.

- Dedicated microprocessor control system with led input/output indicator for simplified checking.

- MPCB for motor protection.

- Pressure & flow for each function controlled by the microprocessor.

- Linear scale for injection, clamping & ejector cylinder.

- Alarm history page.

- Production / hour in vertical – bar for a year.

- Easy export/ import of mould & machine data. (Product cast calculator).

- 100 mould data storage.

- Individual keys for manual function with process mode.

- Printer interface with USB port. Cabinet ventilation & fan cooling.