About Us

Since 1993

We help you to choose best Plastic Injection Molding Machines

Top Notch Manufacturing Capability With Excellent Customer Service Is One Of The Main Reason For Our Existence

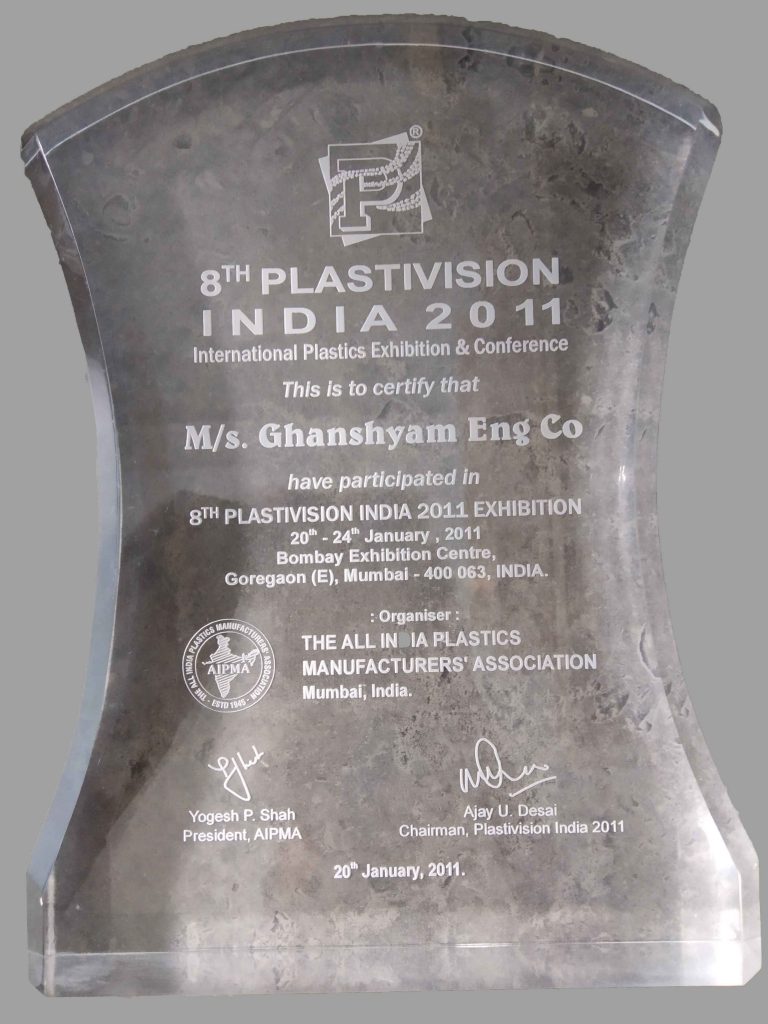

Ghanshyam Engineering Company (GEC) is engaged in the manufacturing and exporting of premium quality Plastic Injection Molding Machines in India. Our journey started way back in the year 1993 with the manufacturing of Vertical Plunger type machines. Since then we have never looked back and are going stronger with our state-of-the-art machinery in 10,000 sq.ft. land area and quality product certifications like ISO 9001:2018.

Our Vision

Our Mission

Our Core Values

Our Journey in Brief

30+

10K+

2K+

8+

Key Management

Mr. Ghanshyam Patel

(Founder & Managing Director)

Mr. Vinod Patel

(Co-Founder & Business Head)

Mr. Maulik Patel

(Director & Marketing Head)

Mr. Kashyap Patel

(Director & Production Head)

Mr. Harshad Patel

(Service Head)

Our Infrastructure

Our infrastructural base is further divided into subunits like quality assurance, sales & marketing, administration, R&D, production, logistic warehousing, etc. All these subunits are aided with the latest machinery and tools that help us to maintain excellent quality standards and streamline our production with the voluminous market demands.

Also, we stay updated with technological developments and upgrade our infrastructural facilities from time to time in order to boost our productivity and quality standards.

CAD/CAM/CAE

Machine Design Analysis

Precision Engineering

Reverse Engineering

2D and 3D Conversions

Assembly & inspection

All of our plastic injection machine manufacturing processes are done in-house in Rajkot, GJ. We encourage customers to come in and take a tour of our state-of-the-art manufacturing facility. It is because we believe that long-lasting and strong customer relationships start with real life interaction.

That is why we are proud to bring MADE IN INDIA plastic injection molding machines to life, because we can deliver quality, confidence and partnership for our customers – something overseas manufacturing companies can’t do. We eliminate the hassle, risks, and long lead times and provide excellent after sales services to our clients.

Our Quality Testing Lab

2-D height gauge

Tensile stress indicator

Chrome thickness tester

All QC instruments

Multimeter